The Process

Industry

In the past ten to fifteen years, there has been a movement within the chocolate world towards more pure chocolate - it is a move away from lower-quality chocolates that have given the “food of the gods" a bad rap and caused it to be associated primarily with"candy".

The truth is that dark chocolate, as much as it may be a treat and a luxury, has health benefits and incredible taste profiles that should not necessarily be relegated to the candy aisle. As more and more people have taken interest in where their food comes from and what is in it, small-batch chocolate makers (and a few larger companies, too) have begun making darker chocolate, chocolate that allows the full flavor of the cocoa beans to be featured front and center. Craft chocolate (like craft beer, craft wine,or craft cheese) is a move towards more pure, more nutritious, and more delicious. If you're going to make craft chocolate, you have to start with great ingredients. Most importantly, you have to start with great cocoa beans.

Beans

We believe that we start with one of the finest cocoa beans in the world: heirloom Arriba Nacional. We at Mindo Chocolate Makers take "bean-to-bar" to the extreme - we start our process as soon as our cocoa beans are harvested from trees in Ecuador. We work directly with a cooperative of organic farmers in Ecuador about 30 miles outside of our operation in Mindo. We purchase only the Nacional variety of cocoa beans--what is considered to be a fine-flavor, heirloom bean—and absolutely won't accept hybrid or diseased beans.

The majority of cacao trees in the world are hybrids designed to grow smaller and yield more fruit. Unfortunately, flavor wasn't one of the primary goals when hybrids were created. On the other hand, the Nacional variety that we use may not yield as much, but the beans have an incredibly complex flavor profile. What we like about the Nacional variety (in addition to its excellent flavor) is that it grows intermixed with other plants and trees that promote habitats for midge pollinators, birds, and other animals. Not only that, many of these magnificent trees are ancient -- they're trees that our farmers' parents or grandparents planted or harvested from. So, the farmers have a special connection to this variety and appreciate that we pay a premium for them. By paying two to three times the fair-trade price for cocoa beans, we've ensured that we receive only the best Nacional beans and encouraged the farmers to resist the hybrid and deforestation trend.

We've been working with many of the same cacao farmers for the past five years. Working directly with the farmers has allowed us to share ideas and continually improve the processing of our cacao. As soon as the cacao is harvested, the fruit and beans within each pod need to be collected and fermented. We ferment the beans for 4-8 days in large cedar boxes, a process that relies upon natural yeast within the air to break down the sugars within the cacao fruit. After fermenting, the cocoa beans are dried in the sun on elevated drying beds for 10-20 days, depending on the weather. All of our beans are dried on long beds at the farmers' cooperative - a fact that you take for granted until you realize that much of the cacao in the world is dried on the ground or on the side of the road where gasoline and other pollutants can easily seep into the beans. After drying we roast the beans and winnow the thin shells away from the meaty part of the bean, referred to as cocoa 'nibs". Like coffee cocoa is roasted in order to caramelize the sugars and bring out rich flavor undertones. Loaded with antioxidants and wholesome fats, cocoa nibs are one of the healthiest foods you can possibly eat.

We then ship the cocoa nibs and beans from Mindo to our facility in Dexter, Michigan. It's already been a long process up to this point, but we're just getting started. In Michigan, we select our most flavorful nibs for our finest and darkest batches. We like nibs that have a lot going on, since the complexity of the nibs will determine the complexity of the finished chocolate. We record the characteristics of every batch of chocolate that we make, and if you look through our records, you'll find all kinds of tasting notes on our nibs : banana, cherry, coffee, fruity, floral, roasted, peanut, red wine, woody,tangy, earthy - even whiskey!

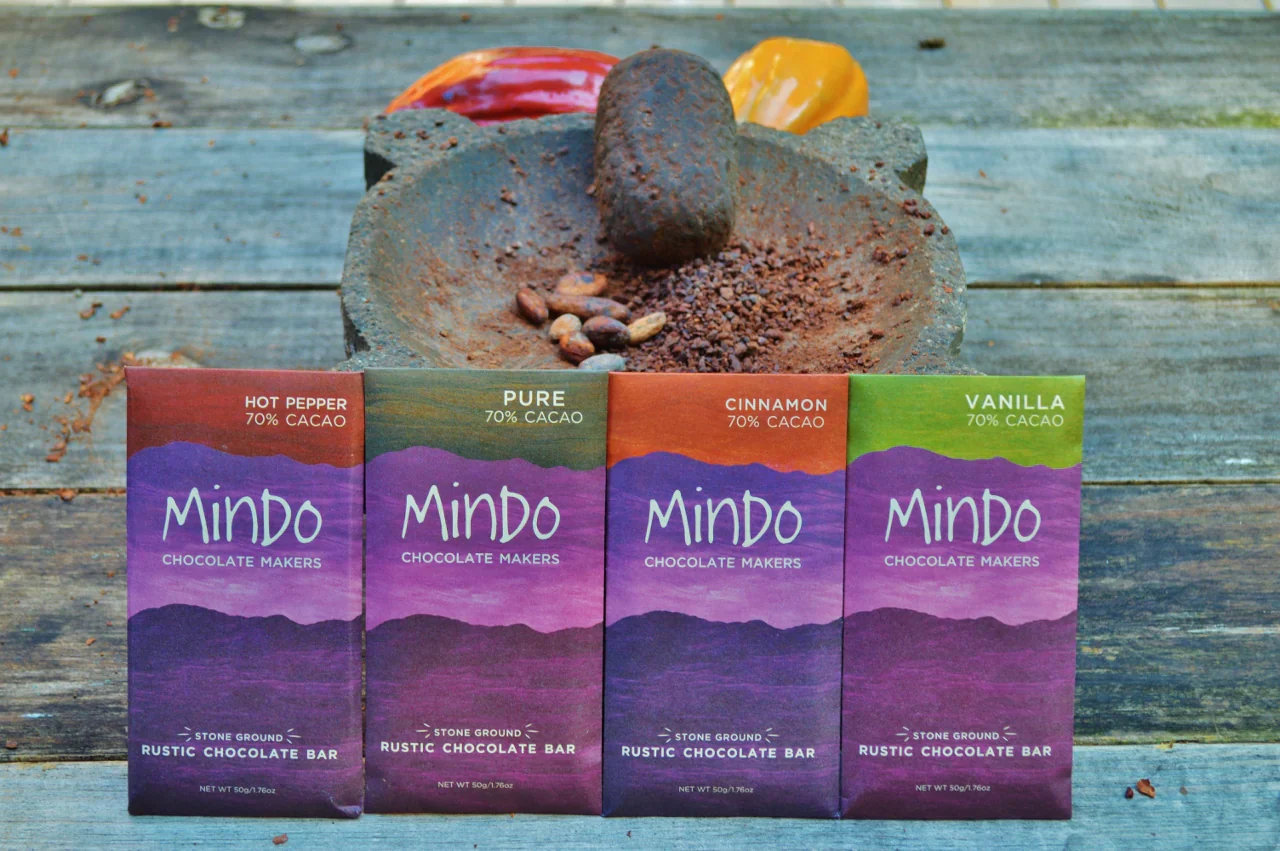

To put it simply, chocolate is made when you grind cocoa beans down. There are a number of ways to do this: we use a large stone grinder to make all of our chocolate. The grinder has two granite wheels that crush the nibs down to a silky-smooth consistency (or in the case of our rustic bars, to a crunchy, unrefined consistency). Grinding the nibs takes time. Unlike other machines that immediately pulverize the beans, our stone-grinder can take anywhere from 20 to 35 hours to get the chocolate to the consistency and flavor that we want. We keep our chocolate very pure, so the only other ingredient we add to the grinder is sugar (organic evaporated cane juice).

Making chocolate would be a whole lot easier if you could simply pour the liquid chocolate out of the grinder into molds. Unfortunately, it's not that easy. Like steel or glass, chocolate needs to be "tempered" before it's molded. Why? A few reasons : tempered chocolate is shiny and has a firm snap, will hold its shape for longer, and doesn't have those whitish, dusty streaks and spots that you might see on a piece of chocolate that has lost its temper. In order to get the chocolate in temper, it needs to be heated and cooled in a very specific fashion just before it's molded.

All of our chocolate bars are carefully hand-wrapped, in biodegradable packaging. We give each product a final inspection to make sure the chocolate is in temper, blemish-free, and as beautiful as it can be before it reaches you. Making craft bean-to-bar chocolate is a long and difficult process and a lot of fun along the way. We think our final product is worth it. We hope you do, too.